|

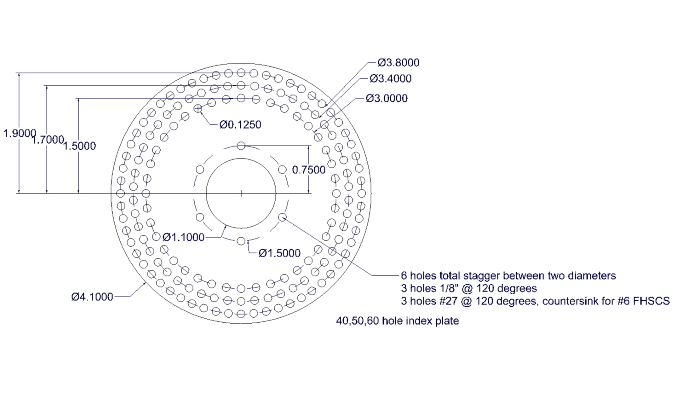

The Index plate. 60 holes 1/8" Aluminum recycled sheet. Made on the Taig CNC Mill. |

|

Here are the dimensions of the 60 hole index plate. Dimensions may vary somewhat. The center hole is now 1.1" so it fits the new spindle. |

|

You will need to make a Centering Plug to mount

the index plate to the pulley. (both items not included with the kit) The centering plug dimension should now be 1.1" rather than .75" as I have changed the design to fit the new spindle. |

|

|

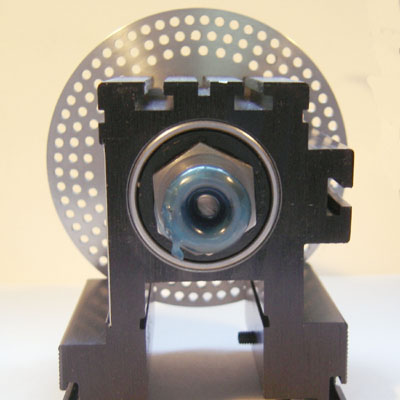

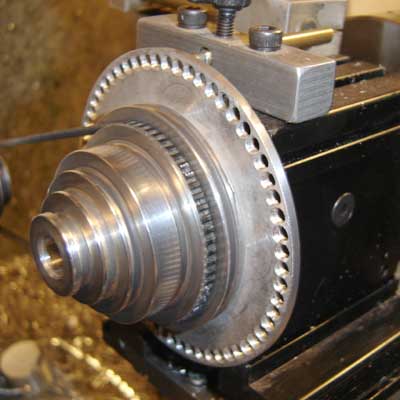

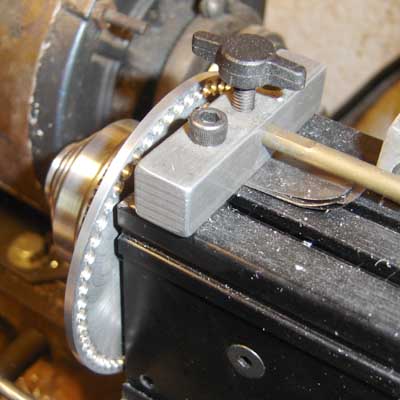

| Index plate mounted to the headstock, showing one design of indexing pin (not included). | Top view. |

| This is one design for the indexing

pin block. Other possibilities: Spring loaded plunger, spring arm, ball

detent... (items not included with the kit) |