An Auxilliary Dead Center for the Taig Lathe

by Keith Brooke

December 2007

Contents

Introduction

Design

Construction

Introduction

There are times when a turning requires both dead center support and tool access to the full length of the workpiece. The Taig's tailstock ram is not long enough to permit this kind of operation. Consider the following photographs.

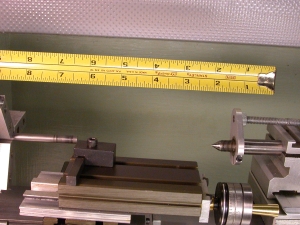

Photo 1: Dead Center Length Needed for Cross-Slide

Photo 2: Dead Center Length Needed for Top-Slide

Photo 1 shows that for the carriage to clear the tailstock when the tool reaches the end of the workpiece, a dead center projection of about 4" is needed. Photo 2 shows that, with the top slide mounted, to turn a taper as long as its travel ( about 1 3/4"), the projection would have to be about 6". Clearly, supporting the work under these conditions requires a longer dead center. This article describes one way to make this accessory.

Design

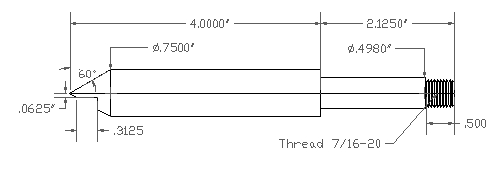

The deflection under load of a cantilevered beam such as a tailstock ram increases as the third power of the overhang and decreases as the fourth power of the diameter. The deflection of a Taig ram lengthened from 2 1/4" to 4" ( 1.78 times ) would be 1.78 cubed or 5.64 times greater than stock. To compensate, it would have to be larger in diameter by a factor of the fourth root of 5.64 or 1.54. Multiplying Taig's 1/2" diameter by 1.54 gives a required diameter of .77" for a 4" overhang. A similar calculation shows a ram overhanging 6" should be 1.04" in diameter. A comprehensive treatment of this subject can be found in the article Understanding Boring Bar Deflection on the Modern Machine Shop website.

To increase the rigidity of attachment, a nut and thread on the end of the dead center draws it tightly against the vertical face of the tailstock. Otherwise, even the slightest gap can allow it to flex at the transition to the smaller 1/2" diameter.

Finally, the center itself is thinned at the tip to permit access by the standard knife tool to the smallest possible workpiece diameter.

Several other authors and personal experience confirm that it is not necessary to harden a dead center. With generous use of grease it will last indefinitely and can be repointed easily should it ever wear.

Construction

The recommended material for this center is 3/4" 12L14 steel although the example shown was made from 20mm who-knows-what that happened to be lying around. The stock Taig tailstock ram measures .4965" and the new one is specified as .498" because that's the largest that would go into my tailstock bore. The 7/16-20 thread is arbitrary. 3/8-24 or other would do as long as a washer is used to span the ~1/2" hole.

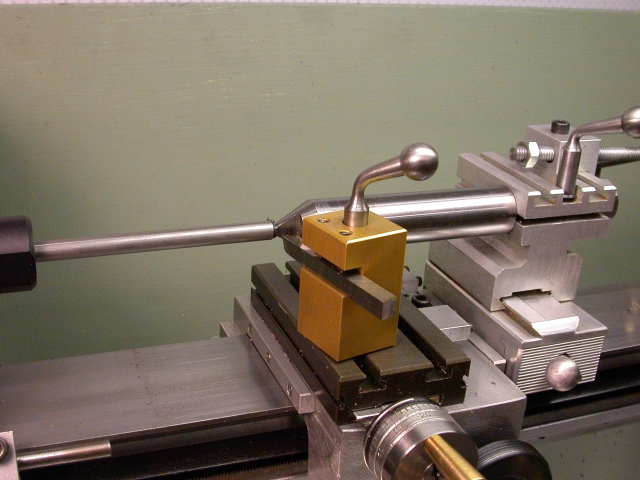

Photo 3: Shank Turning Setup

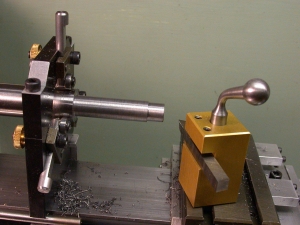

Photo 4: Threading Setup

This is a pretty long workpiece and needs extra support. Start with the fixed steady close to the end and turn the 7/16" section to be threaded. Move the steady in and do the shank section. It takes a fair amount of torque to run the 7/16" thread. The grip of the four-jaw chuck is required, - the 3-jaw will just slip. Photo 4 shows my setup with the die holder locked and the headstock spindle wrench used to turn the workpiece.

Turn the stock around and use the top slide set at 30 degrees to point the center. The relieved section is cut out with a hacksaw and filed smooth. It's exact size is not critical.

Photo 5: The Mounted Dead Center

The completed dead center is secured radially just like the Taig but with the additional 7/16" hex nut tightened to lock it axially as well. This could be dismissed as overkill but, with a light machine like the Taig, any extra rigidity is welcome.

© Copyright 2007 Keith Brooke. Queries and comments welcome. Please put the words 'Taig Dead Center' in your e-mail subject to bypass my junk mail filter.

This document produced with Evrsoft's 1st Page 2000 Version 2.0 Free Edition.

This document produced with Evrsoft's 1st Page 2000 Version 2.0 Free Edition.

![]()