Review of The Beall Tool Company Collet Chuck

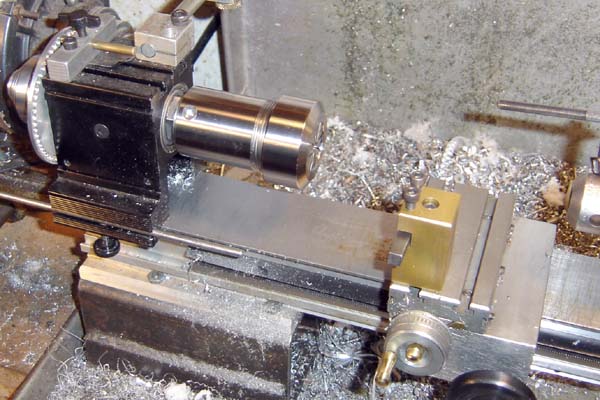

The Beall Tool Company sent me one of their Collet Chucks to review. The collet

chuck is about 3" long and 1.5" diameter, made of steel. The version

they sent me has a 3/4"-16tpi thread, make sure you specify it is for the

Taig as they also make a Sherline 3/4"-16 thread which has no register

section. The collet chuck is also available in 1" 8tpi, 1-1/4" 8tpi

and 1-1/2" 8tpi versions as well for other lathes. The collet chuck utilizes

ER32 collets and comes with a 1/4", 3/8", 1/2", 5/8" and

3/4" collet. ER32 collets can hold stock up to 1/32" smaller than

the stated capacity, unlike other types of collets which can only hold stock

exactly the size of the collet bore. ER32 collets are a standard system and

collets of other sizes can be easily procured from most industrial suppliers

or from The Beall Tool Company.

Once mounted to the Taig lathe the collet chuck was checked for runout and

for each collet was found to be about .0005" or less. Because of the length

of the body you can fit rods up to 2.5" inside the collet holder, thus

keeping the part from having overhang when working on longer pieces. In use

the collet holder grips quite strongly, and provides more clearance around the

part than if you were using a standard Taig chuck. The extra length of the collet

chuck does eat up bed space , but most work on the collet chuck will be short

in nature anyway. Beall sells the collet system primarily for turning wood,

but test cuts on various materials showed it to be just as good for metals from

steel to aluminum. As a workholding system for the Taig lathe it performs excellently

and allows chucking difficult pieces that would be hard to hold with any other

method. If you routinely work on rod stock or dowels this chuck may be the answer

to your frustrations with the limitations of the smaller Taig collet set, as

well as allowing a way of chucking metric diameters of material. UPDATE:

Other users have reported more runout that I found, enough to make the collet

chuck not effective for precision metalworking. I'm not sure why this is the

case, but I thought I would mention it. UPDATE #2: One user who reported

runout received a replacement chuck from Beall that had very little runout and

was very happy with the good customer service.

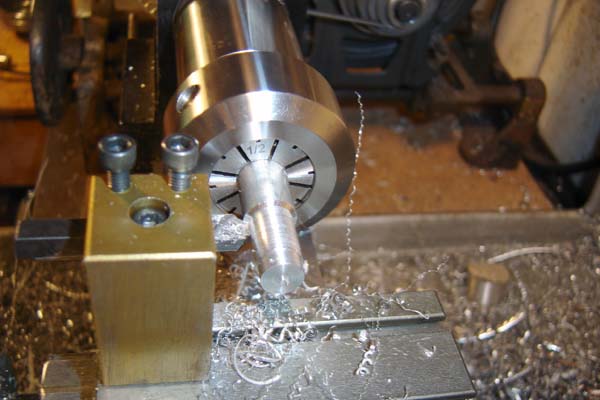

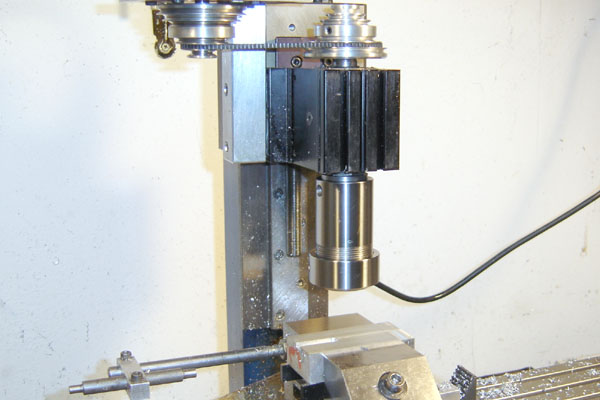

The ER collet system is primarily used in industry for gripping endmills in

a milling machine so I tried the system out on the Taig milling machine as well.

While the length and mass do not make it ideal as an all-around chucking system

on the Taig milling machine, it can be the answer to specific tooling problems.

Often we need to hold special tooling that is unavailable in smaller shank sizes,

such as dovetail cutters and corner rounding endmills, and the Beall collet

chuck is a good solution to that problem. I used the chuck to hold a 1/2"

shank corner rounding endmill, as well as using a 5/8" shank 1" diameter

endmill as a facing cutter. It also is a good way of holding metric shank tools.

All in all the Beall Collet Chuck is an excellently made piece of tooling,

versatile, accurate and will increase the ability of your Taig to do certain

jobs that are nigh impossible with standard tooling. The Collet Chuck is available

from The Beall Tool Company

and costs $159.00 in the version I show in this review.

Back to the main Taig Lathe pages at cartertools.com