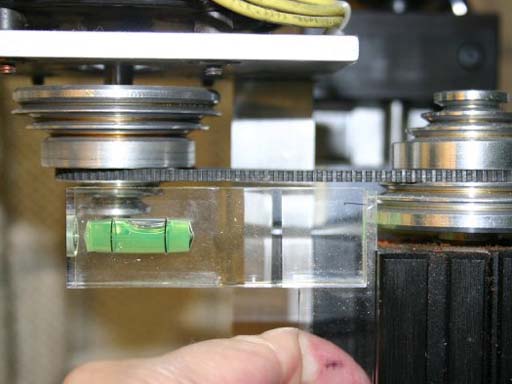

Check groove alignment with a straight edge. The grooves should be well aligned.

Warning!!!

Make sure the motor is unplugged, never adjust pullies with the power connected to the motor!

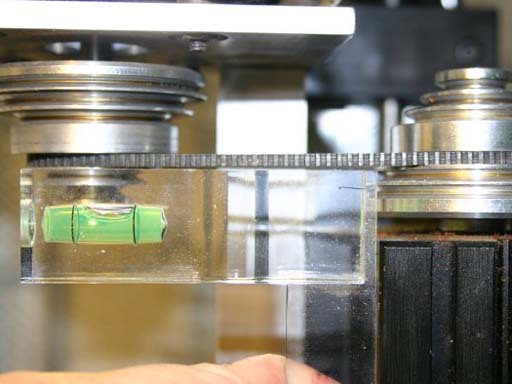

Also check from the side to make sure the motor mount post is perpendicular to the spindle.

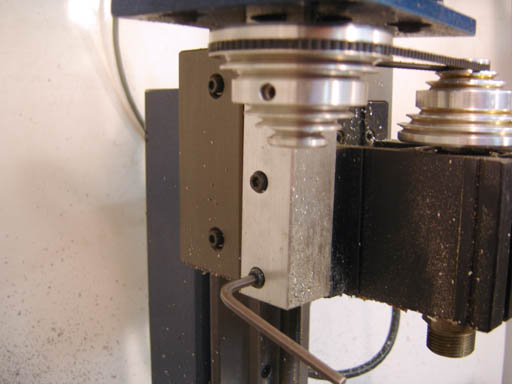

The two allen screws can be used to adjust the post up and down and side to side (twist)

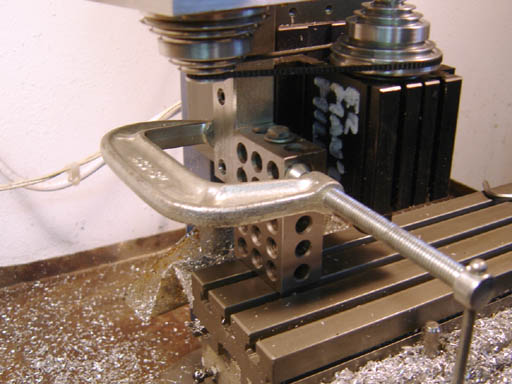

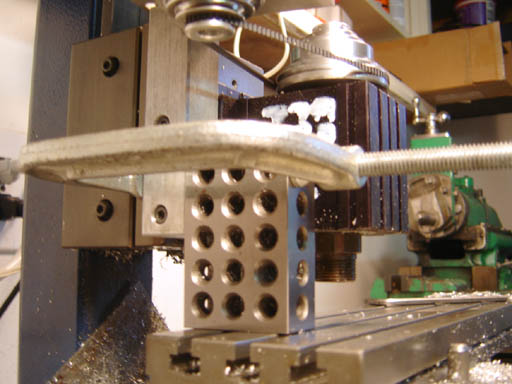

Here's one way of assuring alignment. Mount a 1-2-3 block to the mill table, squarely.

Use the y and z axis feeds to get the 1-2-3 block against the motor mount post, loosen one screw on the post and make sure the post is square to the 1-2-3 block and continue to use the feeds to get the 1-2-3 block in square contact with the front of the post.

Clamp the post to the 1-2-3 block with a c-clamp.

WARNING!!!!!

If you are aligning the pullies on the CNC milling machine, turn off the controller and use the hand knobs on the end of the stepper motors to move the axis. It would be very easy to jam things up using the CNC control with this method.

Here's another view. Now both motor mount post screws can be loosened and the z-axis used to adjust the motor mount post up and down.