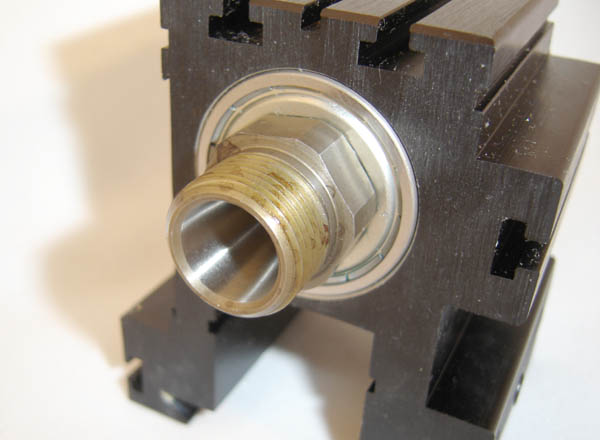

The bearing spacer is now held with one screw and the bearings are a press fit in the headstock housing.

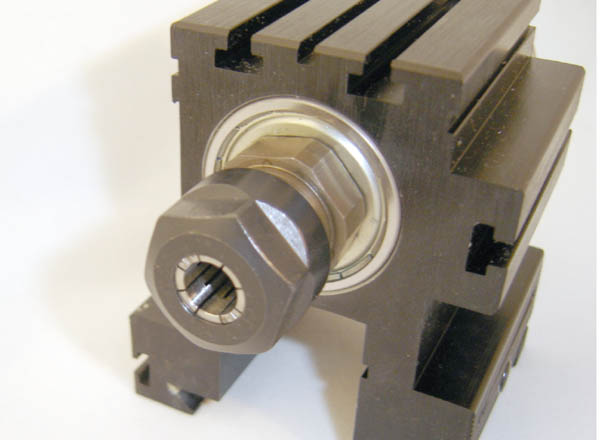

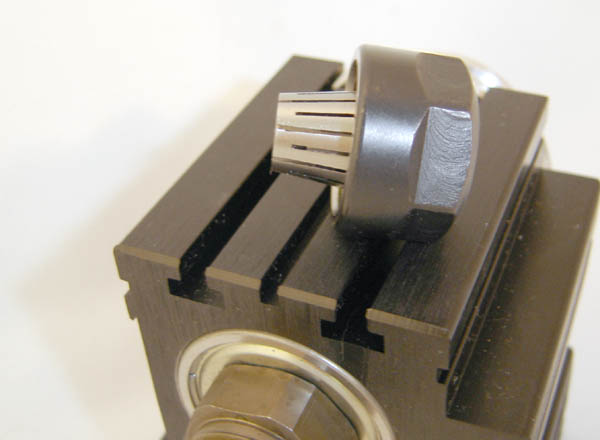

You can see the clamping shoe more clearly in this pic.

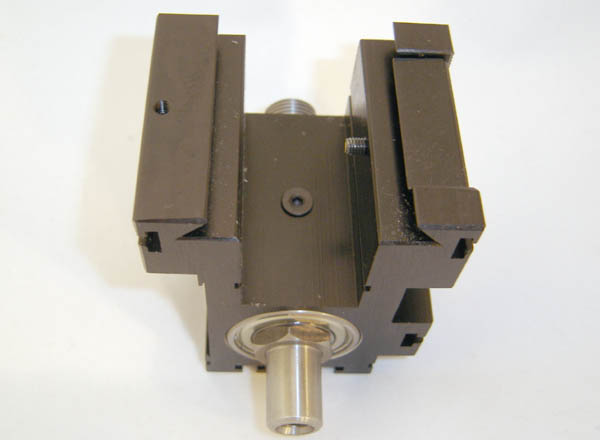

Taig has improved the headstock housing for the Taig Microlathe and milling machine. They also have an ER16 spindle available for the Taig milling machine. Here are some details.

|

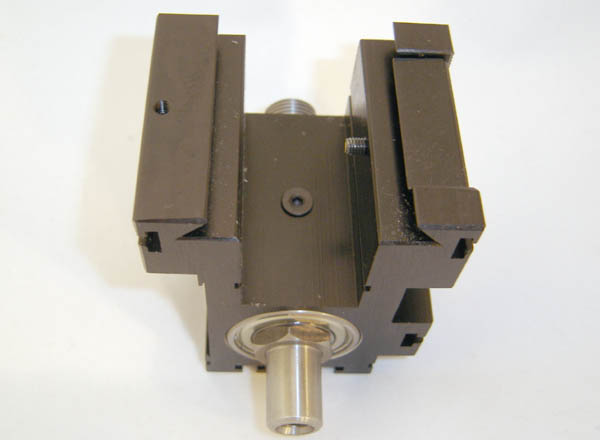

The new housing is one piece. It clamps to the bed of the lathe or the z-axis of the mill by the one screw on the side. This tightens the moveable shoe on the side. |

|

Taig added a second t-slot on the right side to make up for the shoe removing some of the functionality of the bottom slot. |

|

The bearing spacer is now held with one screw and the bearings are a press fit in the headstock housing. You can see the clamping shoe more clearly in this pic. |

|

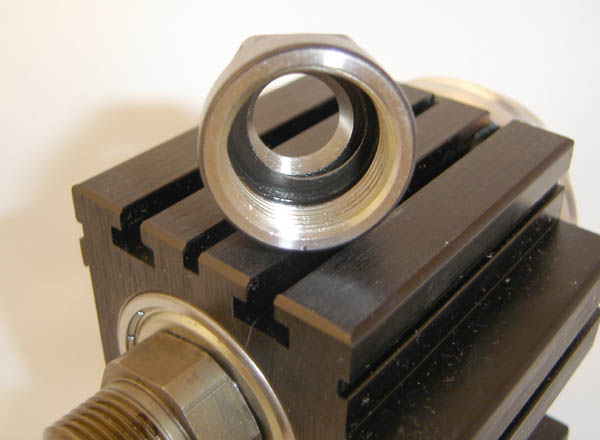

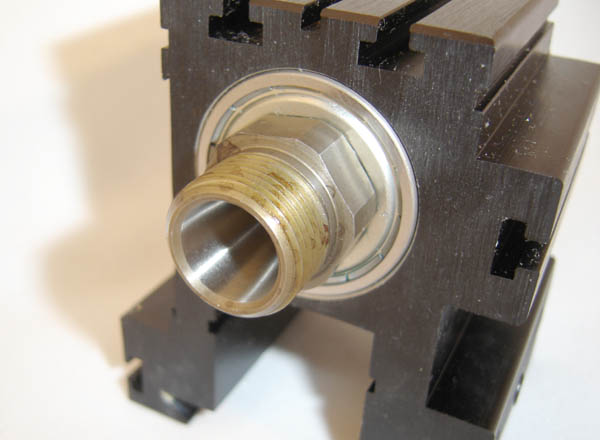

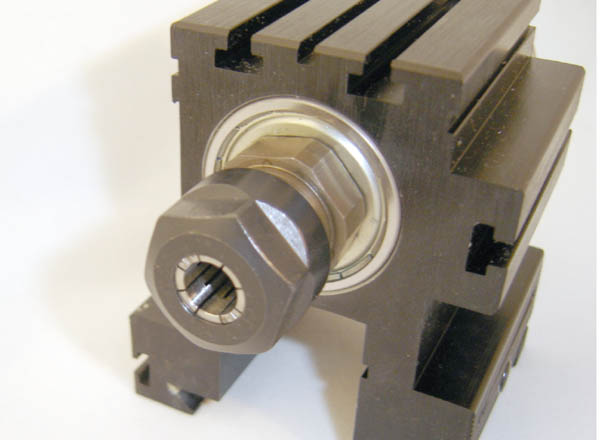

The ER spindle nose. It is bigger than the stock spindle nose and will not accept any screw on tooling. |

|

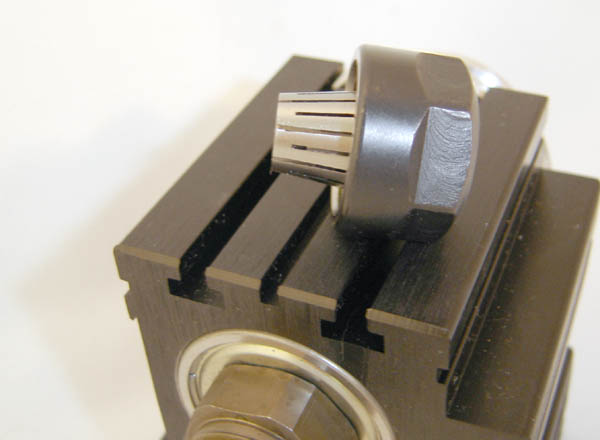

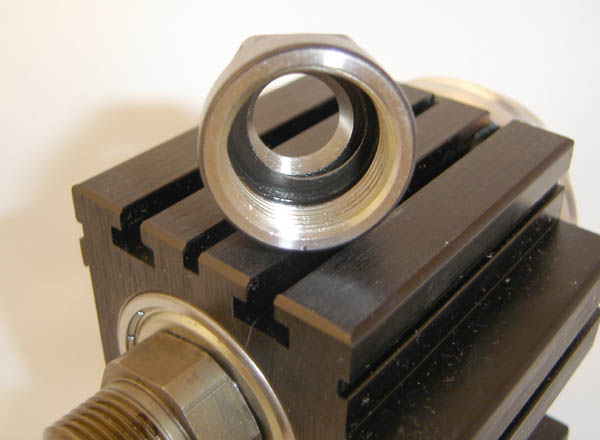

The ER collet nut. Notice the eccentric ring that retains the collet and pops it out when the nut is unscrewed. |

|

To place the collet in the spindle you first place the collet in the closer nut where it is retained by the ring, then screw it in by hand into the spindle. |

|

Do not overtighten with nothing in the collet or you will deform it too much. The ER collets have a collapse range of 1/32" which makes them ideal for holding all sizes of tooling, metric and inch as well as drills. |

|

The new headstock mounted to the mill. Notice the 1/4" roughing endmill with the 3/8" shank in the spindle. This unleashes a lot of the mill's potential. |