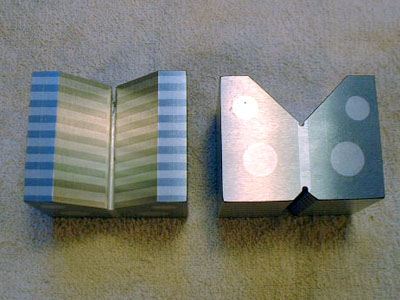

No. 1 "Micro" Magnetic Chuck Parallels, one pair.

$125.00

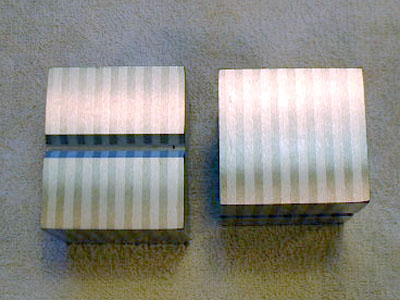

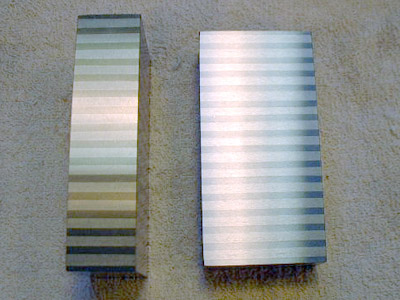

Ground all over to within .0003 and supplied in serial numbered matched pairs.

1"x2"x4"

Integrally cast in one solid piece, not laminated like inferior imports.

Steel used is selected for the highest magnetic transfer and low retention

of magnetic flux

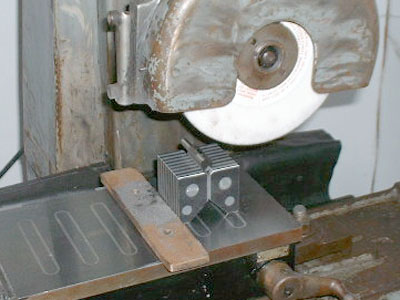

The blocks are used with your magnetic chuck and surface grinder.

(magnetic chuck and 6x12 surface grinder not included)