Fisher Machine Shop

5" "Micro" Sine Bar, 2.5" "Micro" Sine Bar,

Indicator Holder with Accessories

5" Micro Sine Bar

2.5" Micro Sine Bar

Indicator Holder With Accessories

Ordering Information

Back to Fisher Machine Shop

Products

Back to Nick Carter's Taig

Lathe Pages.

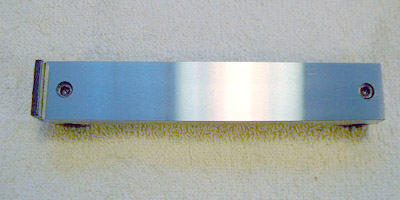

5" Micro Sine Bar

|

|

No. 50SB "Micro" Sine Bar $105.00 |

|

Hardened and precision ground 5" Between centers of rolls. Top parallel to bottom of rolls within .0002 Distance between centers of rolls within .0003 |

|

Refer to Machinery's Handbook for use in finding precise angles using the sine bar and your gage blocks, adjustable parallels or planer gage. (Gage block and massive granite surface plate not included.) |

|

The sine bar is the hypotenuse of a right triangle. The 2.5" gage

block is the opposite leg of the triangle. If we remember the trigonometry

we learned back in high school, sin theta = the opposite over the hypotenuse,

or sin theta = 2.5/5 = .5 (remember, SOH CAH TOA, sin theta=opp/hyp, cos theta=adjacent/hyp, tan theta = opp/adj.) Likewise we can figure the height of the needed gage block for a particular angle by finding the sin of the angle and multiplying by the hypotenuse. sin(30)*5 = .5*5 = 2.5" If you look at the drawing you will notice that the rolls raise the triangle base by the roll radius, this does not matter as the triangle stays parallel to the surface plate. |

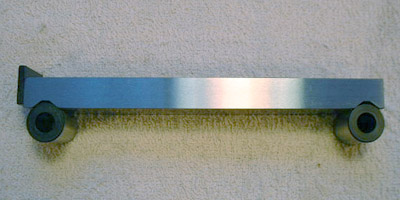

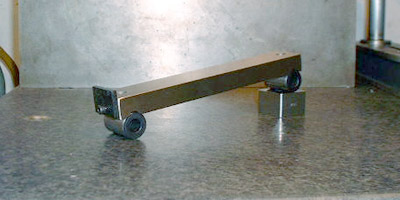

2.5" Micro Sine Bar

|

No. 25SB "Micro" 2.5" Sine Bar A nice short Sine Bar where space is an issue. |

|

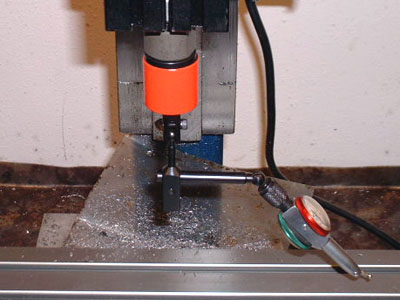

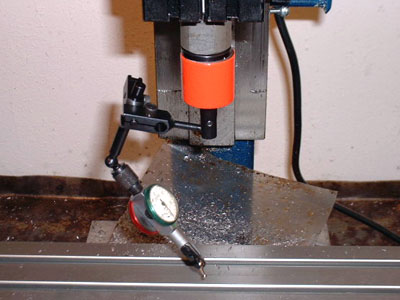

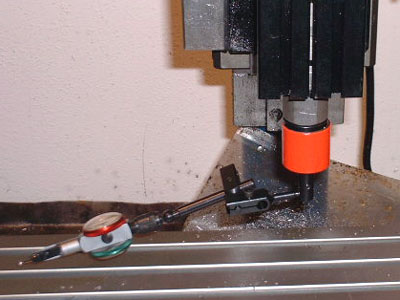

Tom Long generously took pictures of his use of the Fisher

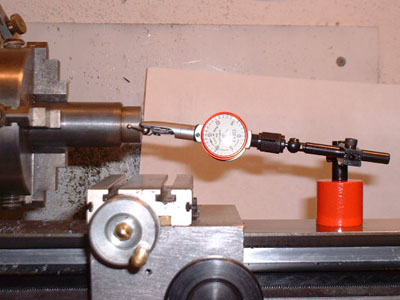

2.5" Micro Sine Bar: I have just made a few pics of the method I use (making use of the 2.5" sine bar I got from you) for setting the lathe compound to a precise angle. I'll send them to you in the next few days. FYI this isn't some "new" or "improved" way of doing it, it's just the way I do it. In this case I need to turn a short internal taper (.301" +/- .005 deep, major diameter to be .169" +/- .001) at 1.71 degrees per side, in a little stainless steel piece. 2.5*sin1.71 = .07460 My "zero" is a 1" gage block; the stack of blocks is .850+.124+.1006, giving me 1.0746. First I set it with a square against the carriage, then I make sure by using an indicator along the length of the sine bar. No change along the length means the angle is correct. If it needs adjustment I just bump it in gently until it's right on the money. Seems like a lot to do but it only takes about 5 minutes. |

|

Using the indicator to verify the setting. |

Indicator Holder With Accessories

|

IH11 Indicator Holder with Accessories $93.00 A Powerful Permanent Magnet Indicator Holder Clamps Indicators with Dovetail, 5/32" or 1/4" Stems. Universal Swivel Joint with Friction Movement 3-3/4" Overall Height Used with the 1/4" Shank Accessory Adapter Can Be Chucked In Mill or Lathe Spindle (Does Not Come With Indicator) |

|

|

|

|

Indicating in a Workpiece in the 4 Jaw Chuck

|

Tramming the Mill

|

|

|

|

More Versatile

|

Great Range of Adjustment

|

Back to Fisher Machine Shop Products

Back to Nick Carter's Taig Lathe Pages.