While reading the Jan/Feb 2005 issue of Home Shop Machinist I noticed an advertisement of the Nano-Tram, for tramming the head of the Taig and Sherline milling machines. I contacted the Accudyne Corporation and asked for a sample of the product to review. I received it several days later and put the tool to it’s advertised and unadvertised uses. Although I tested the Nano-Tram on the Taig Mill, I am sure it would perform equally well on the Sherline or other small benchtop mills.

|

|

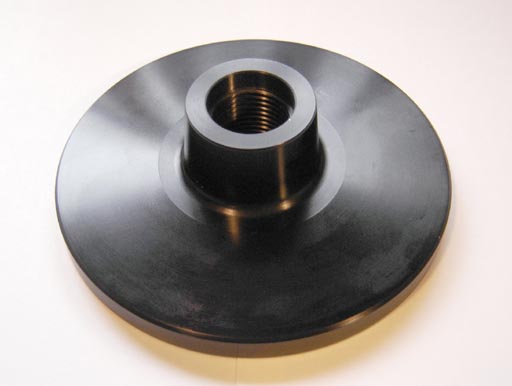

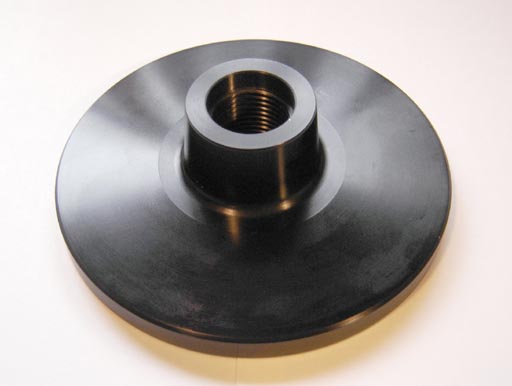

| 1) The Nano Tram Top. | 2) The Nano-Tram Top |

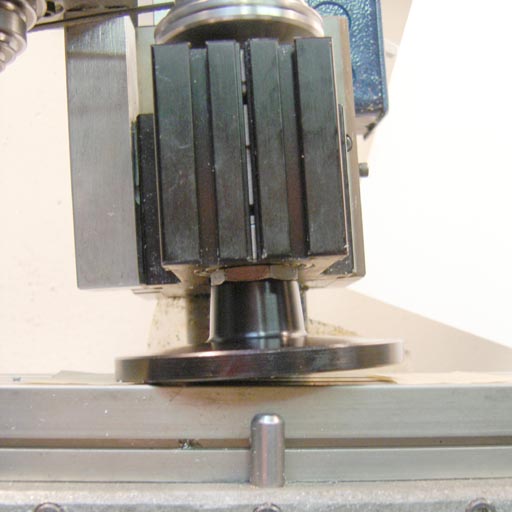

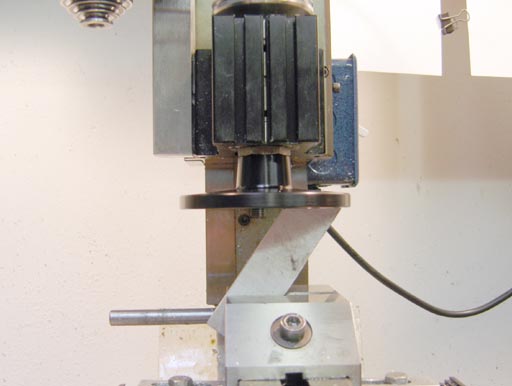

The complete Nano-Tram system consists of two separate products, The Nano-Tram Top (pictures 1 and 2) and the Nano-Tram Base (picture 3). The Nano-Tram Top is a hard-anodized aluminum faceplate 3.75” in diameter, available with a MT-1 mounting for the Sherline milling machine or a ¾”-16 tpi mount for the Taig milling machine. On the Taig version Nano-Tram has the spindle threads and boss perpendicular to the face within .0002”

|

|

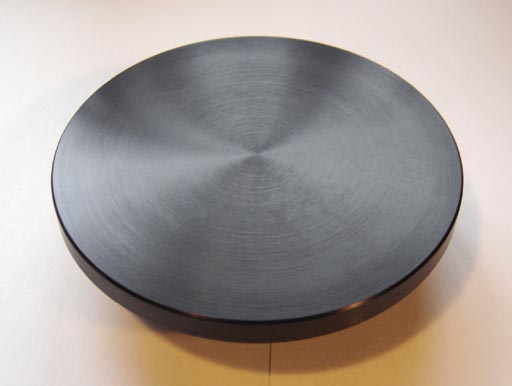

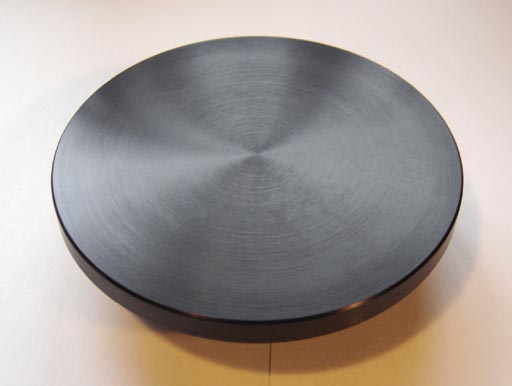

| 3) The Nano-Tram Base | 4) I screwed the Nano-Tram Top onto my Taig milling machine spindle. |

The Nano-Tram Base is a steel table 6.5" long x 5.375" high x 4.5", with the top and the feet of the table ground to .0003”

I screwed the Nano-Tram Top onto my Taig milling machine spindle (picture 4) after deliberately putting the column out of tram. I lowered the head down to the table surface and could visually see the out of tram condition (picture 5).

|

| 5) I lowered the head down to the table surface and could visually see the out of tram condition |

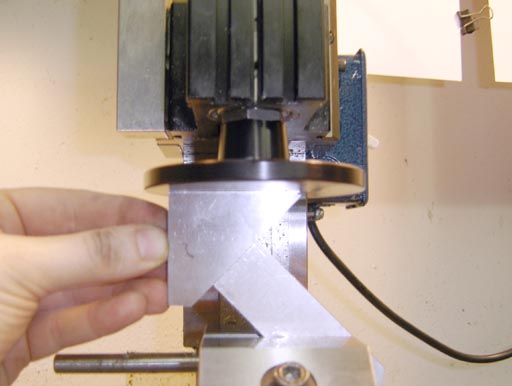

The Taig mill headstock can be positioned at different heights on the z-axis slide, and it must be in it’s lowest position for the Nano-Tram Top to contact the mill table (although you can also use the Nano-Tram Top against a 1-2-3 block, vise or other parallel object if you have the head set in the higher positions). I then placed two pieces of rolling paper (which I first miked to make sure they were of the same thickness) on either side of the Nano Tram Top, between it and the table (picture 6). The use of the paper protects the surface of the gage from damage. It is imperative that the spindle and the table of the mill be clean before using the Nano-Tram Top.

|

| 6) I then placed two pieces of rolling paper (which I first miked to make sure they were of the same thickness) on either side of the Nano Tram Top, between it and the table |

I loosened the column bolt on the mill and gently moved it as I screwed the Nano-Tram Top down onto the surface of the mill. I tested contact by making sure that the tension on the rolling papers was the same. Confident that I made full contact with the paper on either side I tightened the column bolt. I then removed the Nano-Tram Top and tested the alignment with a .0001 dial test indicator. I found that the mill column was in alignment by .0015 over 10” which for a machine tool like the Taig is about as good as you can get without spending a huge amount of time chasing the last tenths. The Nano-Tram Top is a lot quicker than using an indicator to sweep the table and a lot less frustrating. I suspect that over time as I learn the feel of the Nano-Tram Top I could get the column in tram to even more accuracy.

The cooking guru Alton Brown (“Good Eats” on the Food Network) counsels against buying any kitchen tool that is a “uni-tasker”, in other words only good for one job. Believing that to be good advise for shop tools as well, I decided to see what else the Nano-Tram Top could be used to gauge.

The first use I came up with is setting the angled face of a workpiece parallel to the table of the mill. I placed a piece in the vise and used the Nano-Tram to square the angled face (picture 7); normally this would be somewhat difficult to do but the Nano-Tram Top made short work of it. The second use was setting the face of a workpiece at an angle using a 45 deg angle gage (picture 8), normally this would be done in reference to the table or vise but there are situations where the rest of the workpiece is hard to access anywhere but from the top.

|

|

| 7) I placed a piece in the vise and used the Nano-Tram to square the angled face | 8) The second use was setting the face of a workpiece at an angle using a 45 deg angle gage |

I then used the Nano-Tram Top to set the column of the mill at an angle using a vernier protractor (picture 9). This usually would be a somewhat difficult task, as you would sweep an angle gage or sine bar with an indicator in the headstock, while laboriously adjusting the column through many iterations of measurement. The Nano-Tram Top did it quickly and easily.

|

|

| 9) I then used the Nano-Tram Top to set the column of the mill at an angle using a vernier protractor | 10) Setting the Nano Base on top of the mill table straddling the vise, I then retrammed the head with the same success as before. |

Setting the Nano Base on top of the mill table (picture 10) straddling the vise, I then retrammed the head with the same success as before. The base allows you to bridge work that is already set up, which as anyone who has had the column shift out of tram when in the middle of a job is a very convenient ability.Keeping in mind other uses, the Nano-Base would also make an acceptable small surface plate (I would perhaps brace it as it is a bit top heavy for that use).

|

|

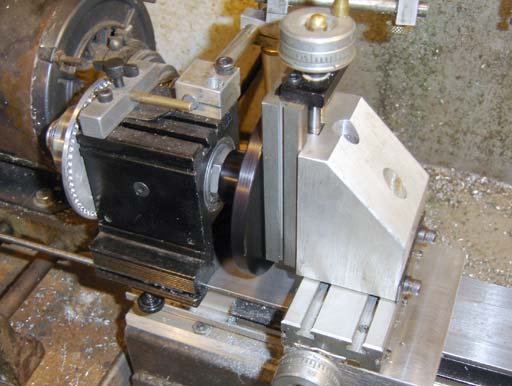

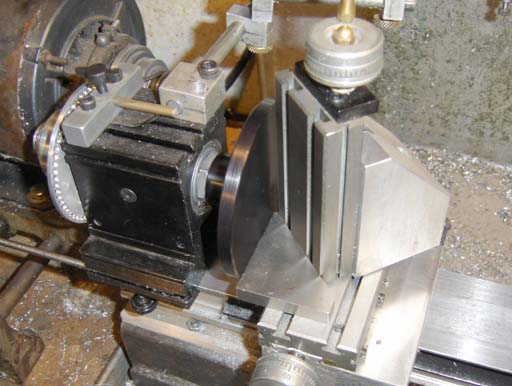

| 11) I used the Nano-Tram Top to set the compound using a 45 deg. gage | 12) The Nano-Tram Top is just as useful setting the milling attachment square |

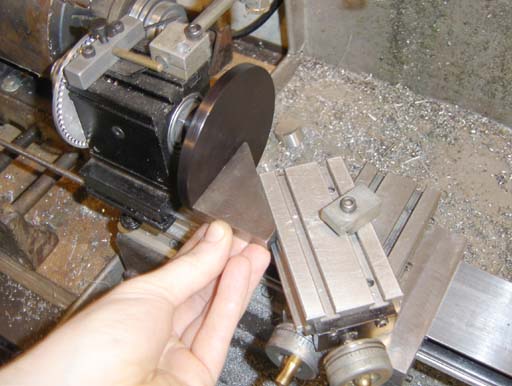

The Nano-Tram Top is also useful on the Taig lathe. The Taig lathe compound is simple and requires the use of a protractor or indicator to set it at an angle. I used the Nano-Tram Top to set the compound using a 45 deg. gage (picture 11). The Nano-Tram Top is just as useful setting the milling attachment square (picture 12) or at an angle (picture 13) as it is on the Taig Mill.

|

| 13) The Nano-Tram Top is just as useful setting the milling attachment at an angle |

The Nano-Tram performs as advertised and is a quality product made in the U.S.A. It is available from the Accudyne Corporation, on the web at www.eztram.com and from Littlemachineshop.com. Accudyne also makes the EZ-Tram for tramming larger milling machines with the vise in place, as well as other useful shop tools.