|

| Basic

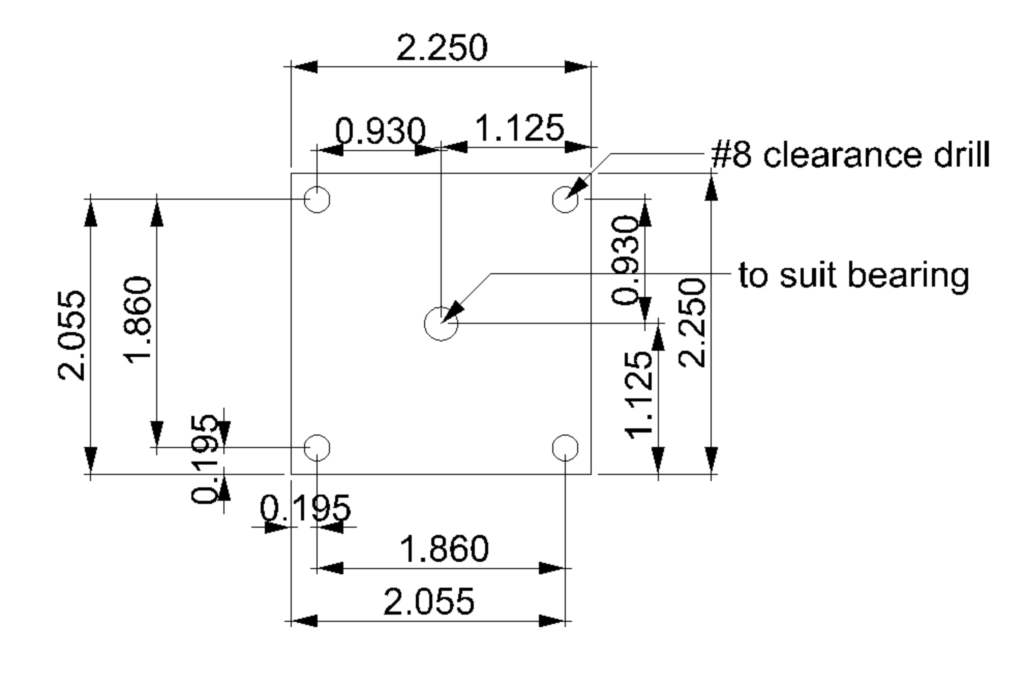

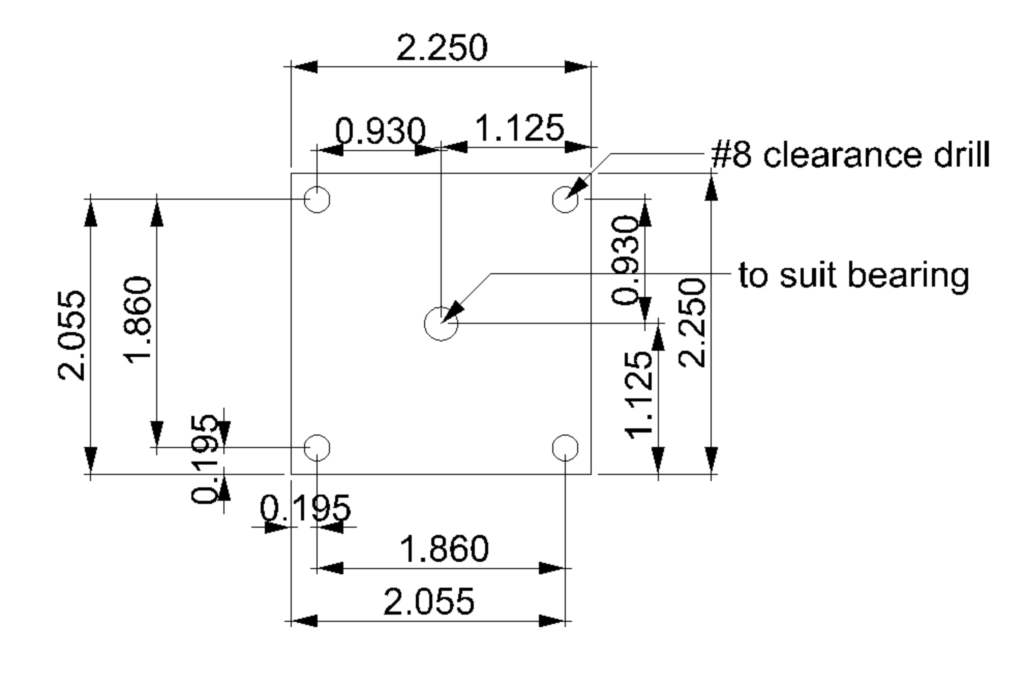

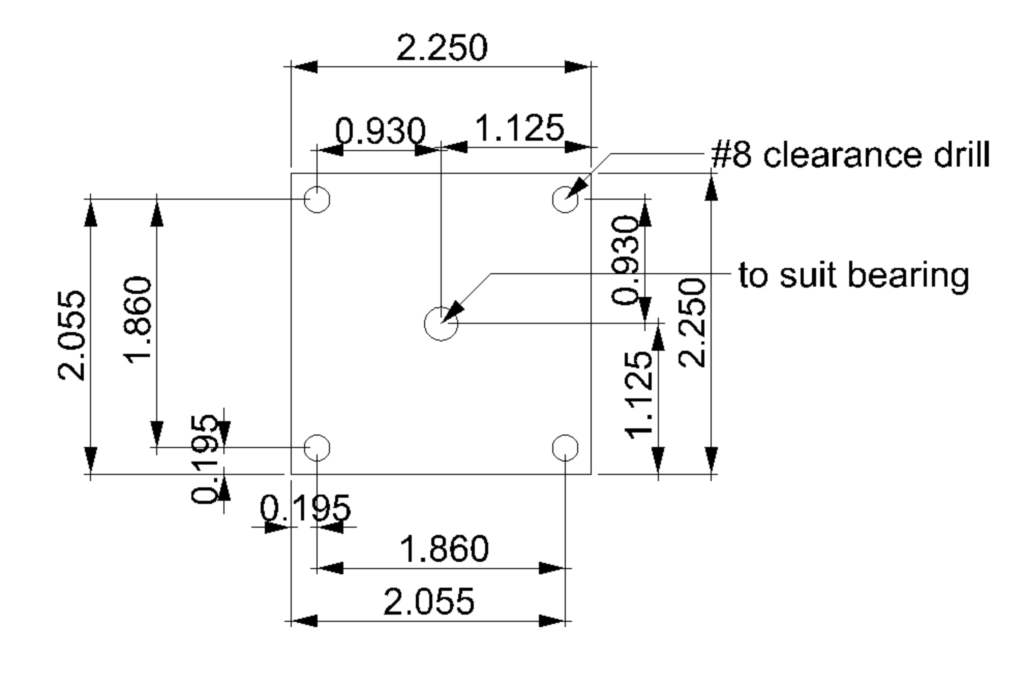

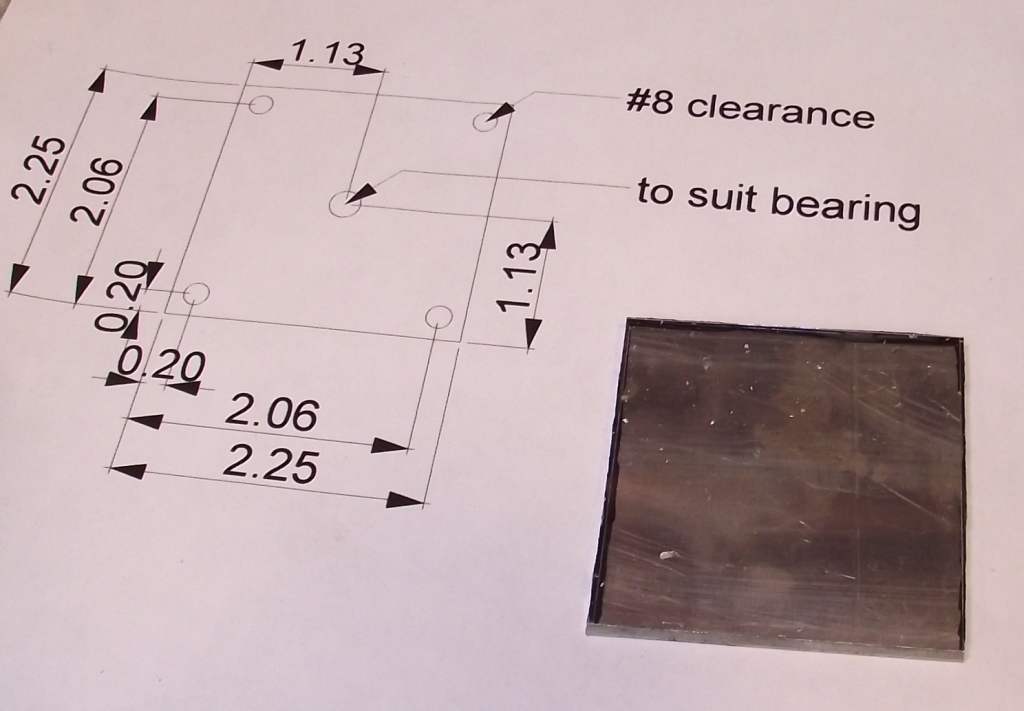

dimensions of the plate. Drill the clearance holes for the #8 screw

oversize so you have wiggle room. The bearing hole should be a press

fit w/ whatever bearing you make. |

|

| Need to make a plate that couples that crank with the stepper mount. The stepper mount is tapped. |

|

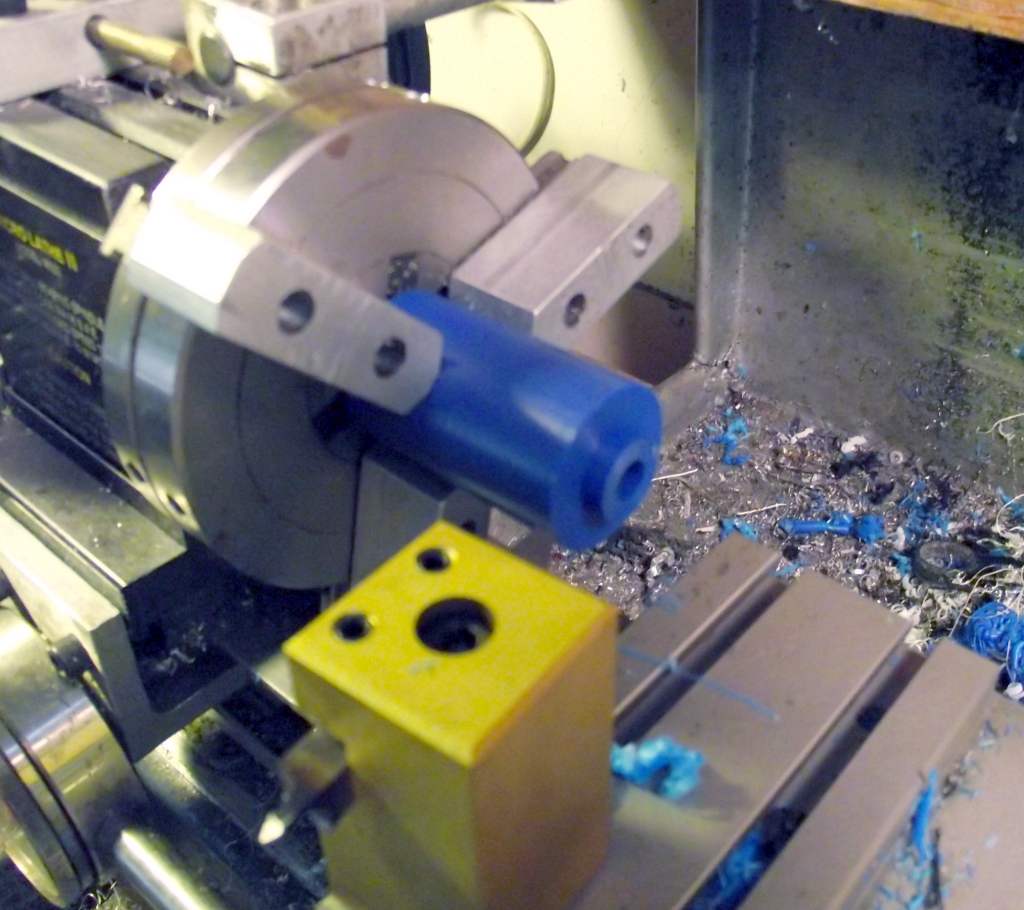

| Some scrap plate cut roughly to size before milling. I think it was .156" thick. You could use any thickness you wanted. |

|

| Milling to size. |

|

| Finding edges. |

|

| Drilling the mount holes. |

|

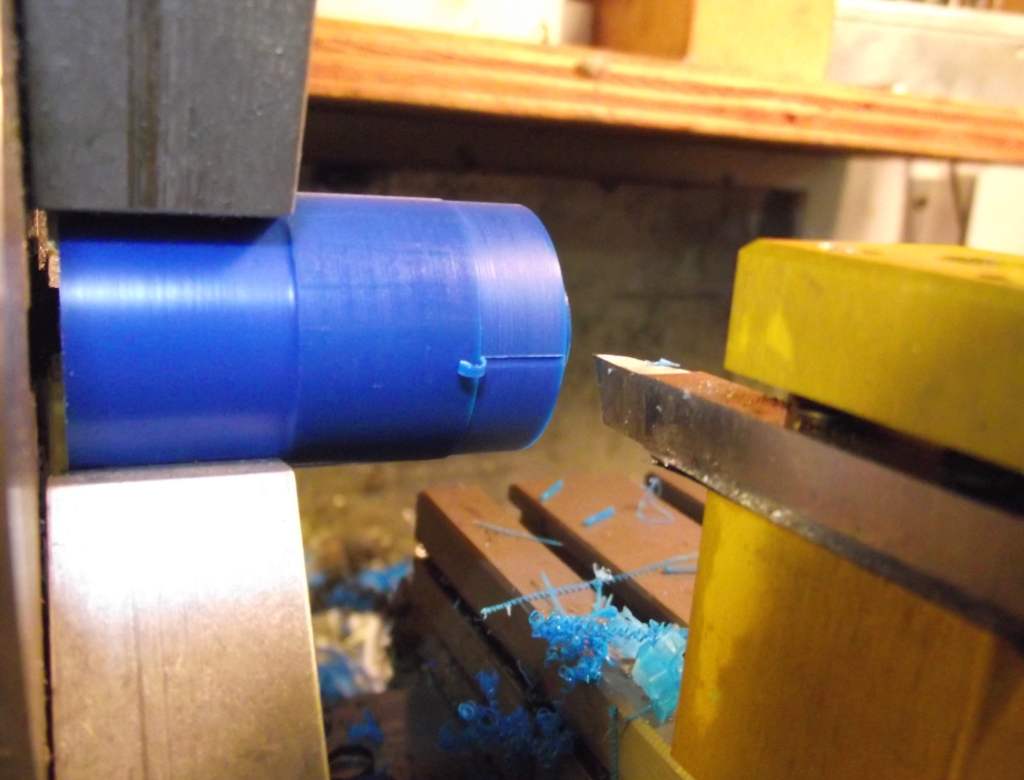

| Turning the bearing from Acetal. Brass or any other bearing material would work. |

|

| Scribing an index mark. |

|

| Drilling

the hole. If I had planned better I would have gone with a 3/8" hole

& 3/8" bearing minor OD. I had to use a stubby drill for a 1/2"

hole... |

|

| Filing a flat on a length of 1/4" steel shaft for the setscrew that couples the shaft to the shaft coupler. |

|

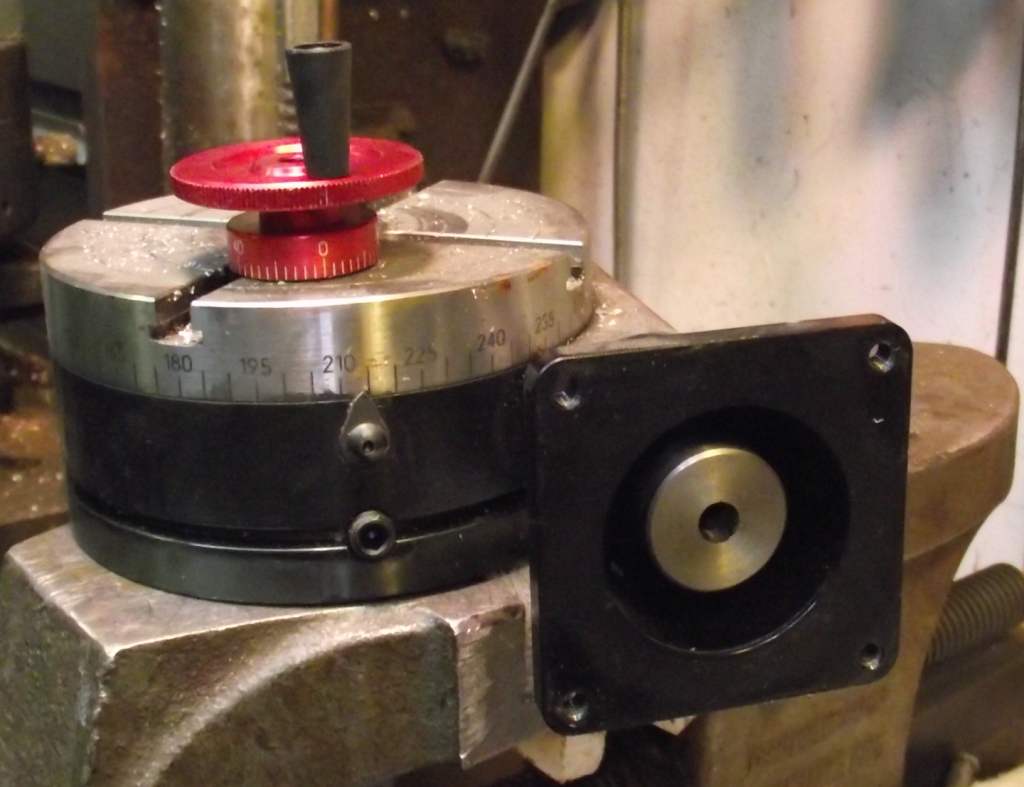

| Mounted.

If you use something slippery for the bearing you may need to add a dab

of glue or in my case a couple of prick marks inside the bore of the

plate to keep it snug. |

|

| Now the CNC ready rotary table can be used manually. |