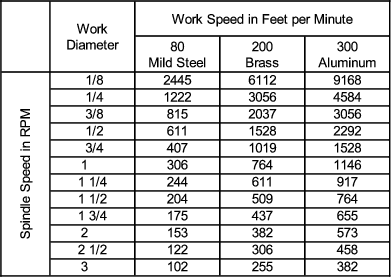

Fig. 4.1: Recommended Turning Speeds

The three most common workpiece materials are mild steel, brass and aluminum. With high-speed steel cutters, the classic speed recommendations, shown in Fig. 4.1, are 80 sfm for steel, 200 for brass and 300 for aluminum. At these rates, the minimum Taig speed of 586 rpm will handle diameters of up to .52” in steel, 1.30” in brass and 1.95” in aluminum.

The Taig cross-slide has a travel of 1.75” and, with riser blocks, this radius can be swung over the cross-slide. So the lathe is capable of turning workpieces of up to 3.5” diameter. At their respective recommended sfm, this would require spindle speeds of 87rpm for steel, 218 for brass and 327 for aluminum. Of course, one can turn at faster speeds and slower feeds but this should be a choice, not a necessity. And when cutting off, you often don’t even have a choice.

Since most lathe users consistently do work that is too large for their machines, the Taig will unquestionably be expected to do work that can only be completed successfully at lower than its stock speeds. That means devising a replacement drive system.