A Universal Expanding Ring Mandrel for the Small Lathe

By Nick Carter

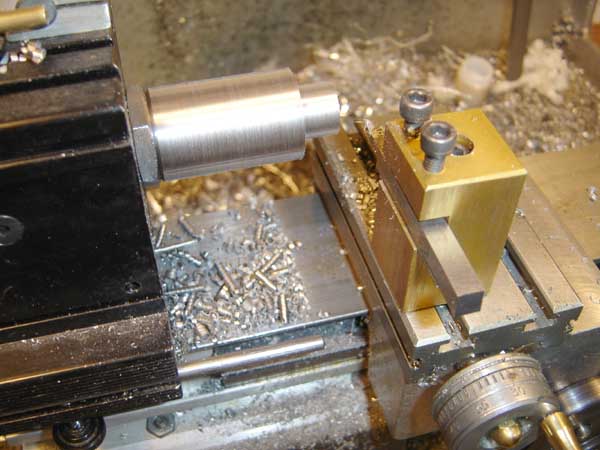

The other week a friend came by the shop for some jewelry related lathe help.

She was using a ring holder meant for benchwork (GRS Benchmate) to chuck her

rings, both waxes and metal) for turning. While her holder worked, I thought

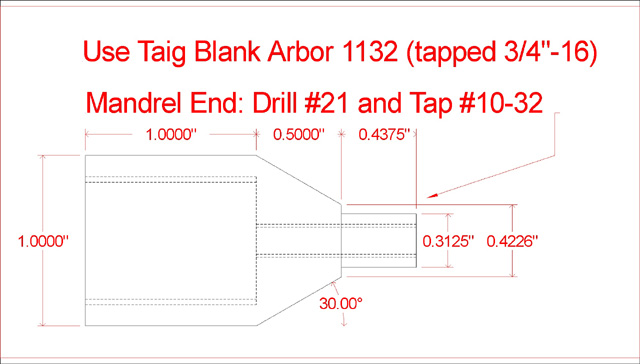

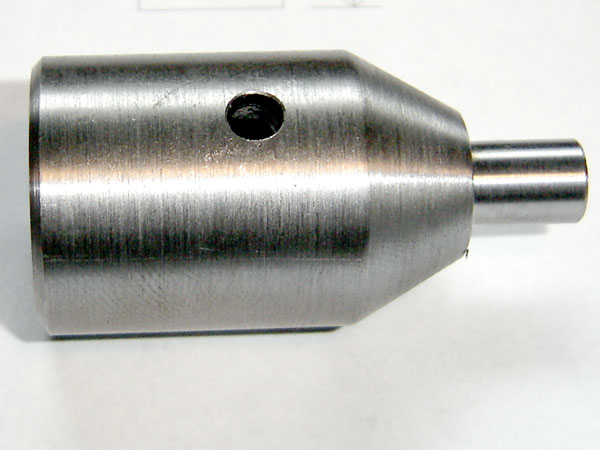

I could come up with something better. Based on the Taig #1132 Blank Arbor,

the mandrel shown here could be made with a straight shank as well, for mounting

on a variety of lathes. As shown it will work on the Taig lathe, and if you

turn down the end of the blank arbor for about 1/8", on the Sherline lathe

as well. If you want to make it with a straight shank, you should chuck up some

1/2" rod in your lathe chuck, turn the end down to 1/4" dia for about

1" to 1-1/2", then chuck that 1/4" shank in a 1/4" collet

on your lathe (Taig, Sherline and watchmakers collets all are available in 1/4"

internal diameter)

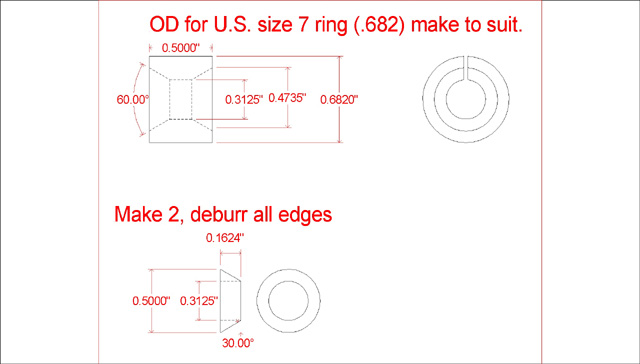

A note on materials, the 1132 is made from free machining steel, I also made

the two conical washers of free machining steel. You could use any metal you

wanted for the conical washers. The expanding arbor is made of Delrin, but again

you could use any plastic, metal or even a hard urethane rubber.

Because of all the pictures I have divided this article into two parts. Part

2 is here.

Continue with Part 2

Back to Nick Carter's Taig Pages