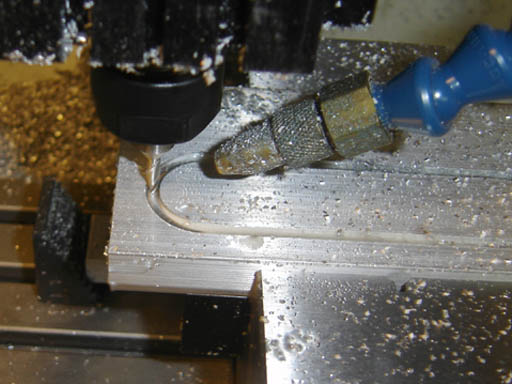

Machining Jewelry on the Taig CNC Milling Machine

Experiments in Rapid Prototyping, Direct Production and Die Making

By Nick Carter, June 12th, 2007

For the past few months I have been playing with various methods for producing

jewelry with my Taig CNC milling machine. Felice and I have been making jewelry

for 20 years, but I haven't worked at it much since the kids came along. This

changed when we started our

store on etsy.com, which allowed us to show pieces that were a bit unusual

(geeky) which wouldn't ordinarily sell in our usual venues. I have achieved

a small measure of success (that is, I have sold them!) with the designs shown

in this article.

Often jewelers will buy a CNC milling machine for one purpose, to make waxes

used in investment casting. I think that in order to innovate or just to use

a machine that may lay idle between custom waxes, a jeweler needs to look at

tools not for what they know they can do or what they bought them specifically

for, but what they might be able to do. So, in the spirit of thinking outside

the box I embarked on the series of experiments shown here.

Part 1: Milling Jewelry

Part 2: Engraving Jewelry

Part 3: Milling Dies for Hydraulic Die Forming

Part 1: Milling Jewelry

Part 2: Engraving Jewelry

Part 3: Milling Dies for Hydraulic Die Forming

Back to cartertools.com