|

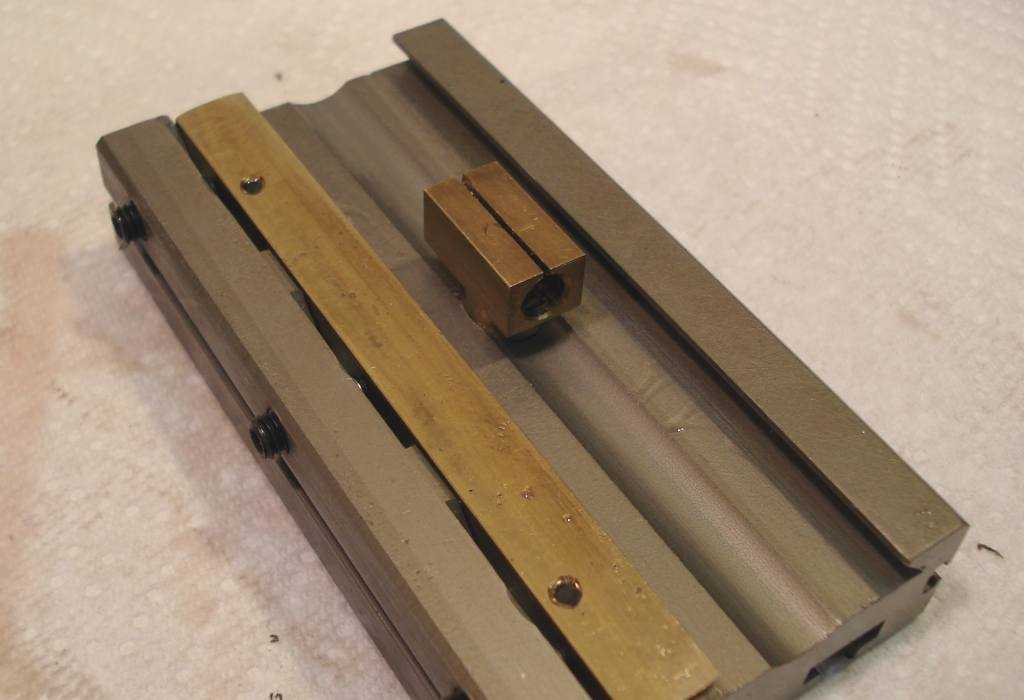

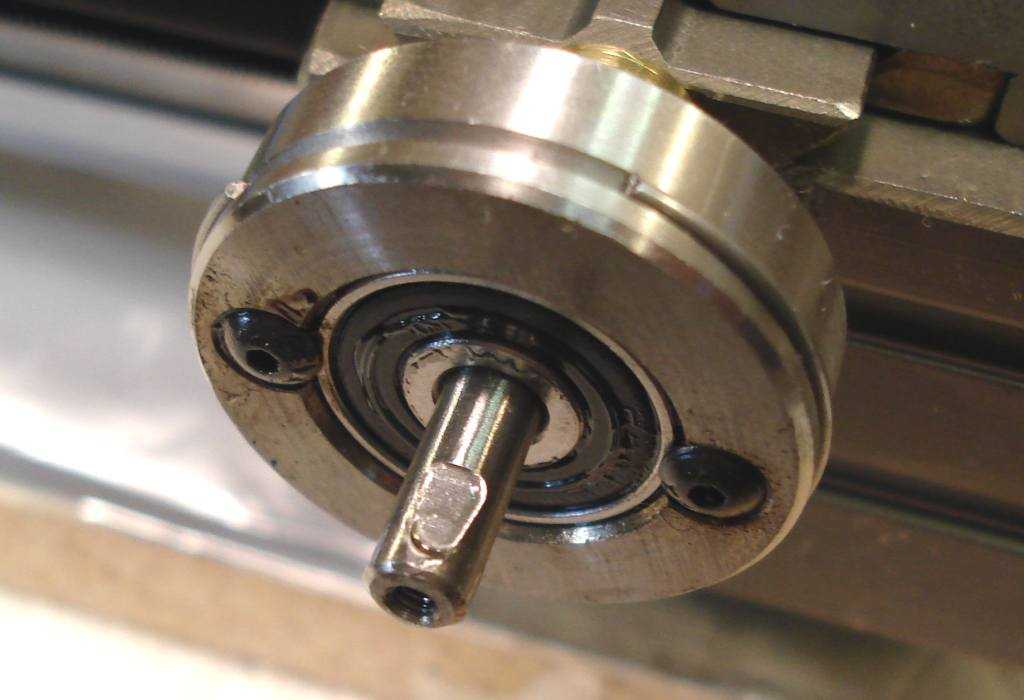

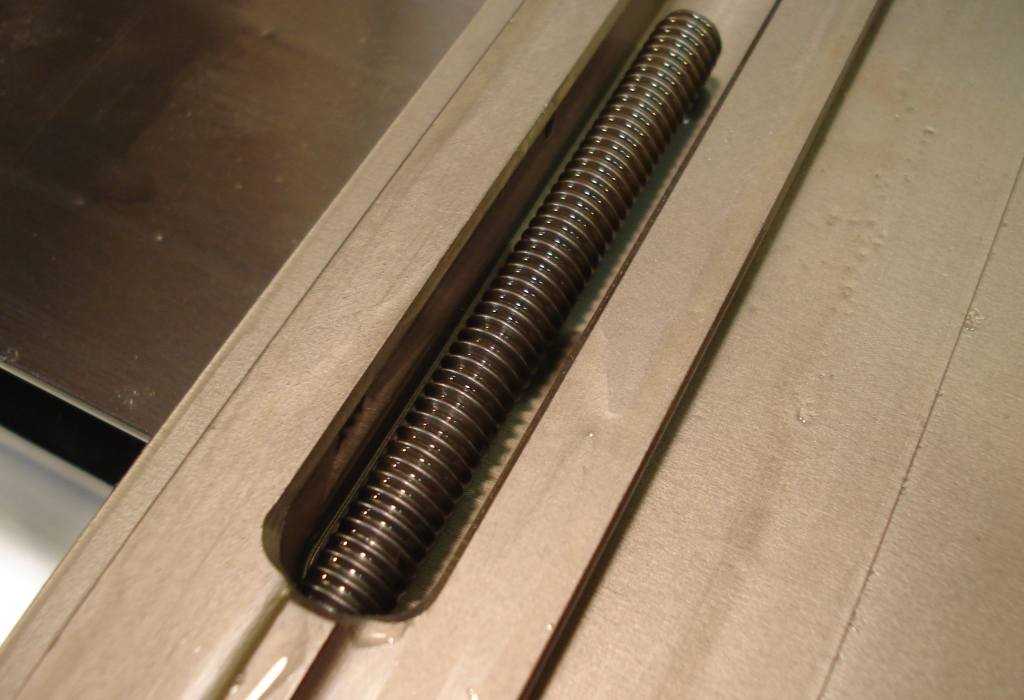

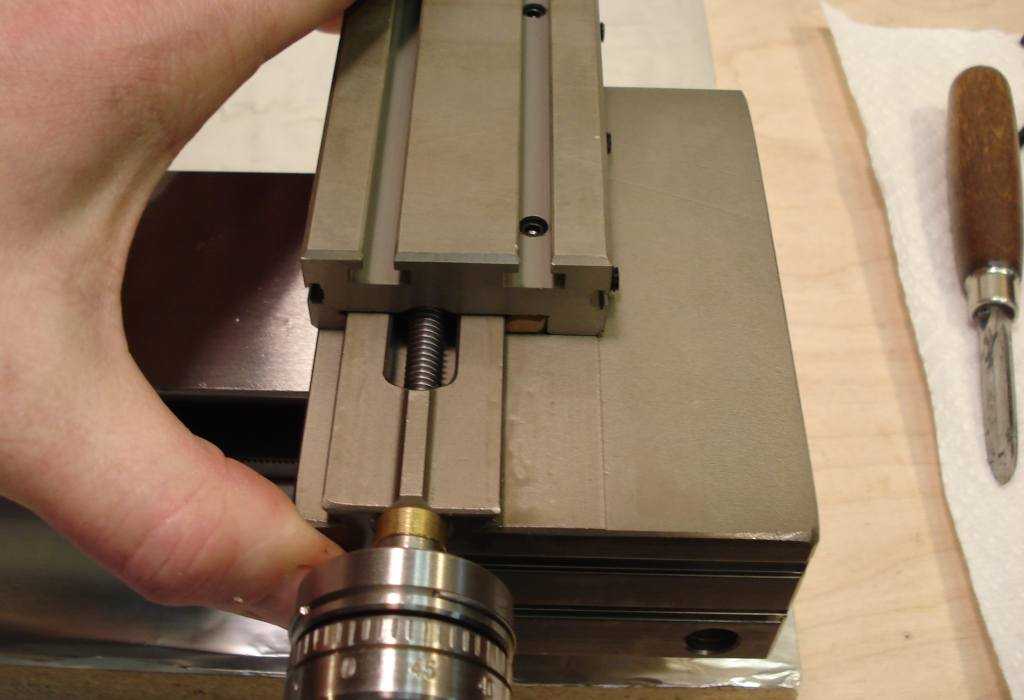

| The cross slide screw assembly. Unscrew the lead screw nut (left hand). |

|

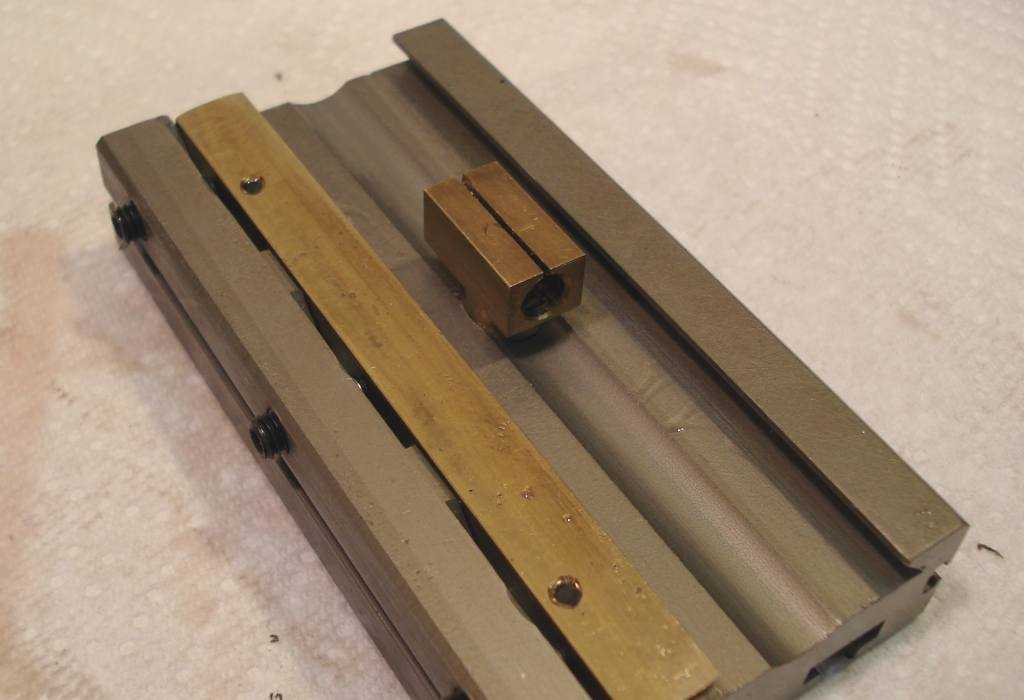

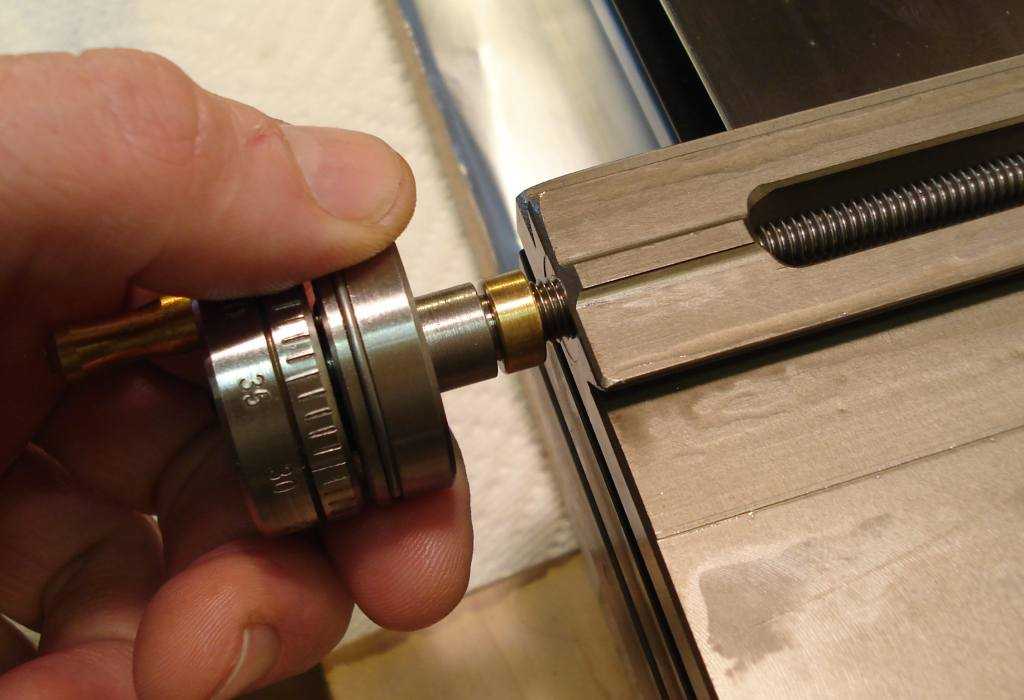

| There

is usually a burr in the hole and the nut post may be a bit tight, some

creative deburring will make assembly easier. |

|

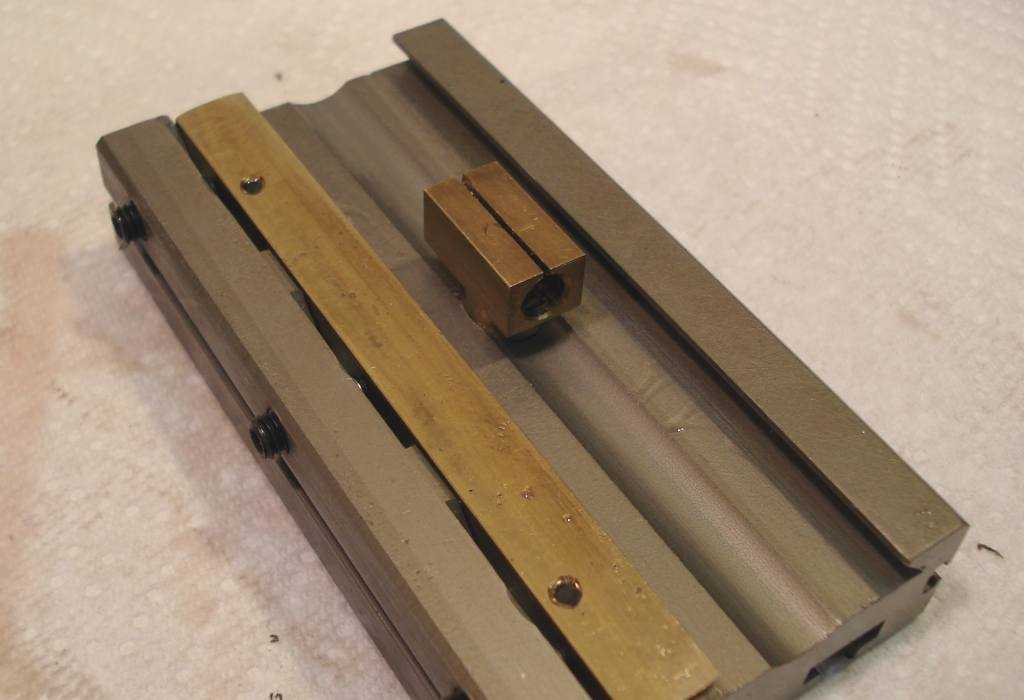

| Deburred. |

|

| The mounting hole and the nut, you want the long end facing away from the front of the lathe. |

|

| Tapped in with a mallet. |

|

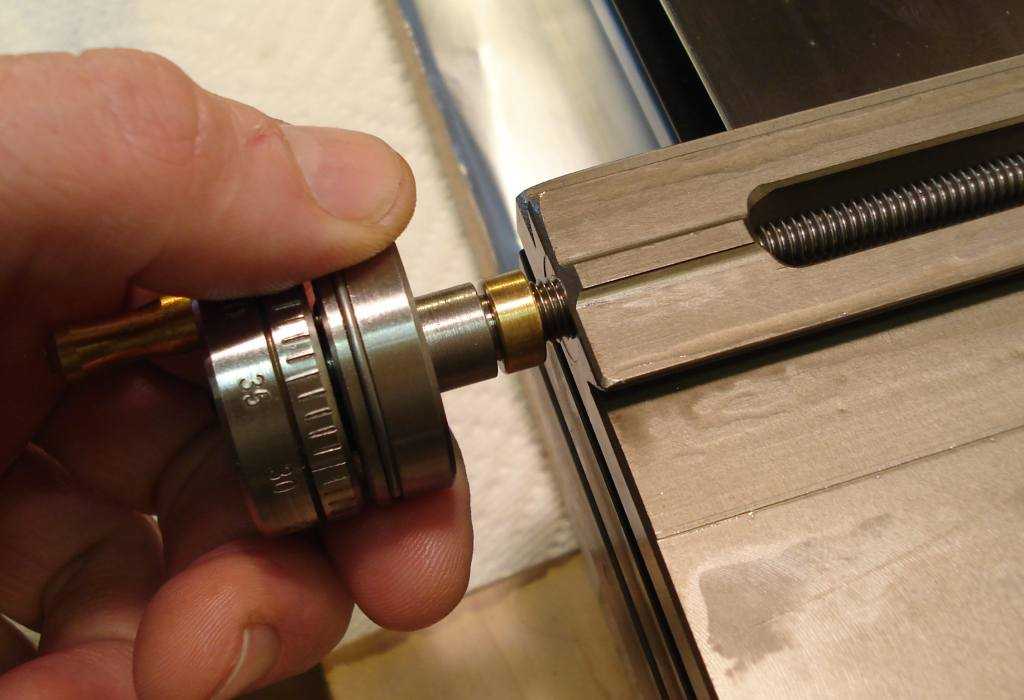

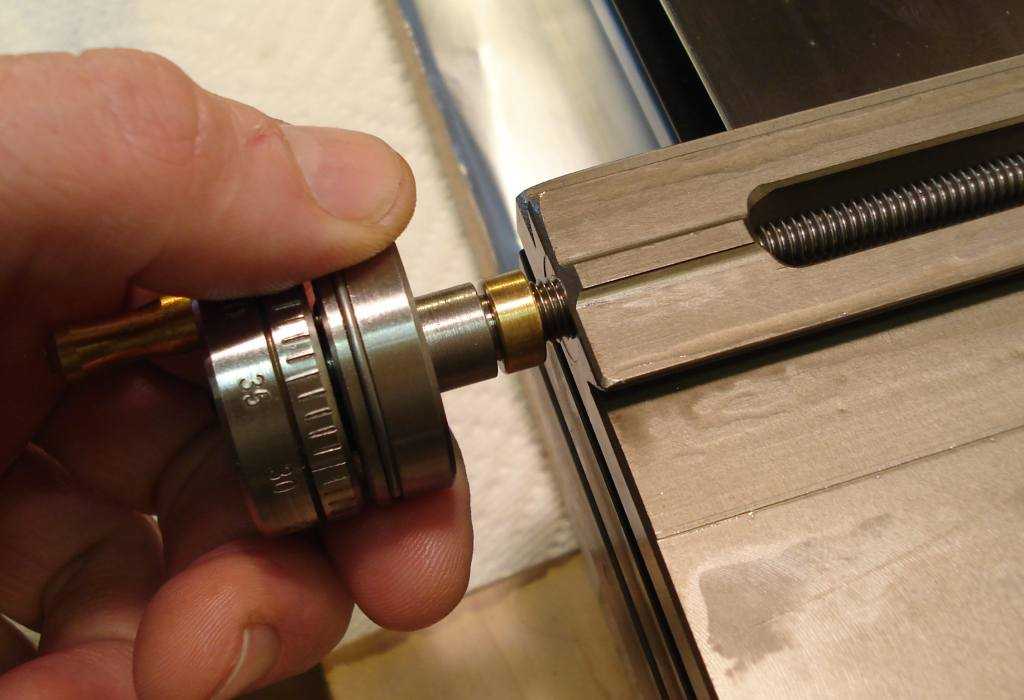

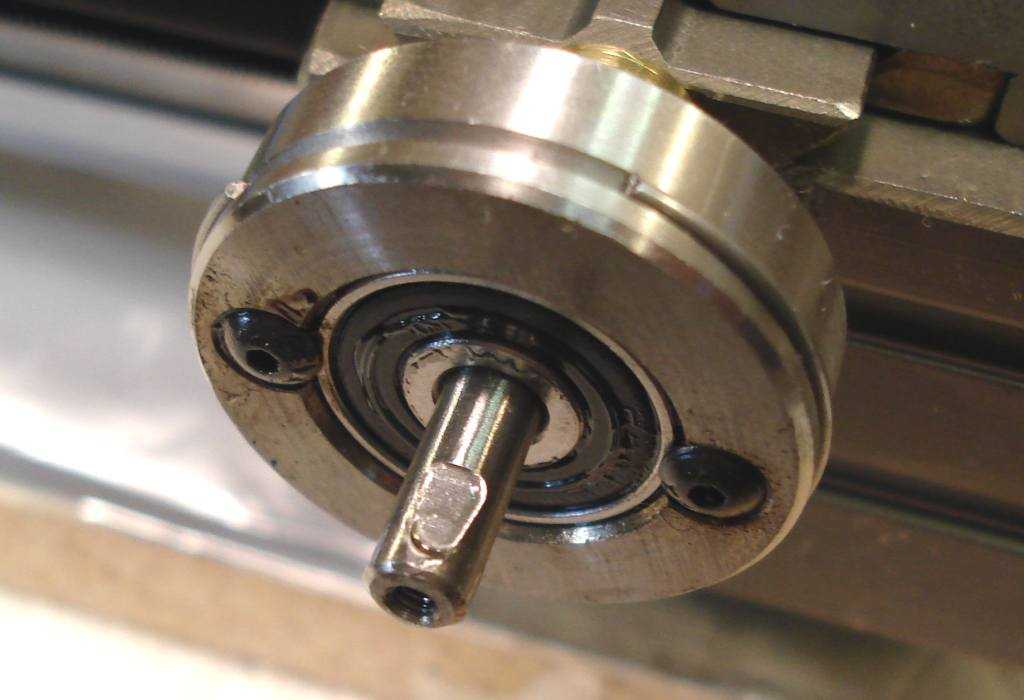

| Screw in the cross slide screw assembly. |

|

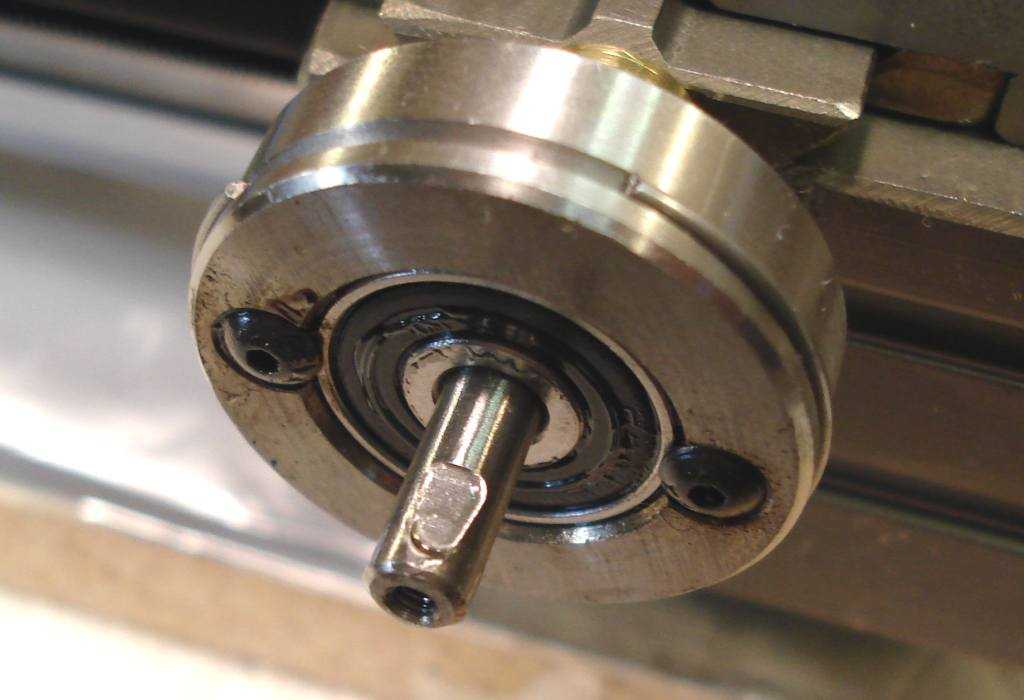

| That ring provides a zero mark. |

|

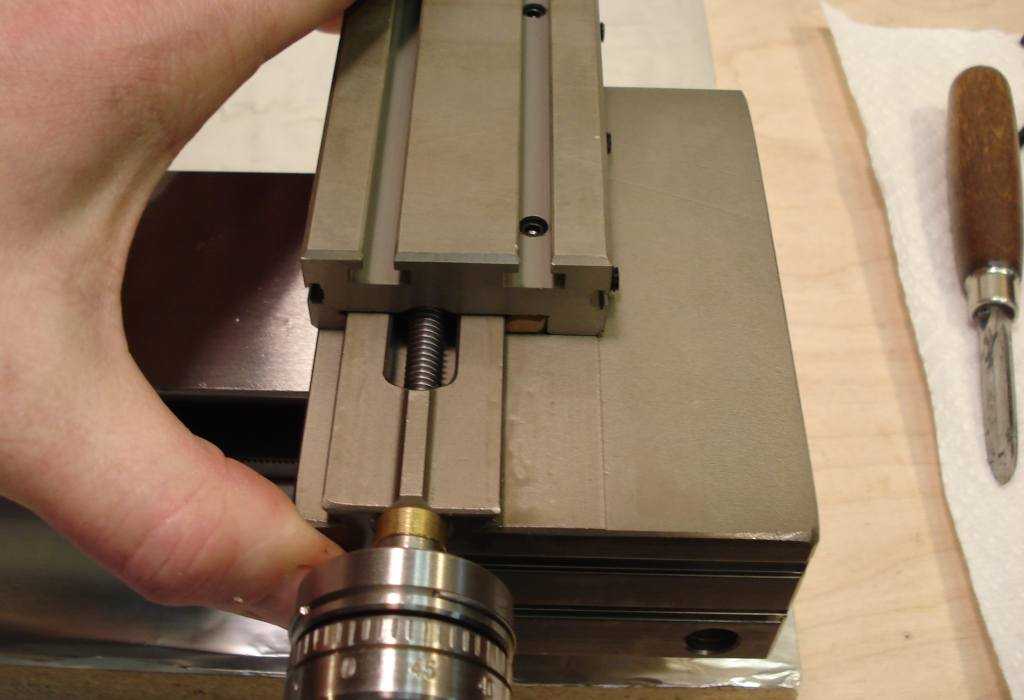

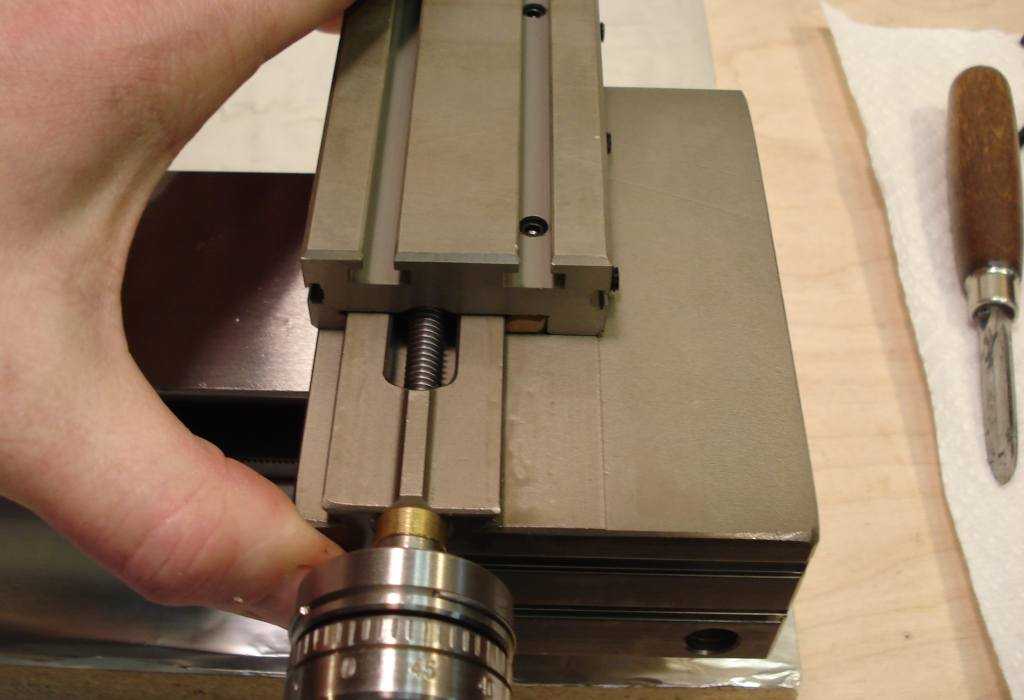

| Screw the cross slide on. |

|

| Oil everything with either 20 or 30 wt oil or better yet, way oil. |

|

| Test for smooth travel. Adjust gibs, tweak the nut alignment, etc to make smooth. |

|

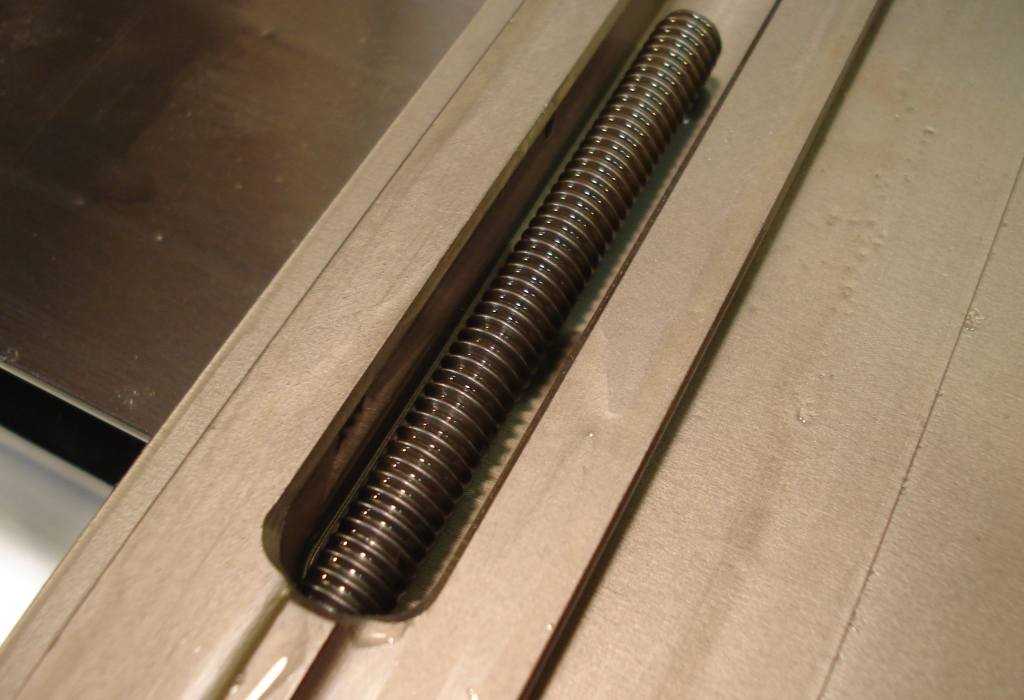

| These steps aren't needed, but here just in case you need to adjust the dial. Remove dial lock screw. |

|

Dial setscrew.

|

|

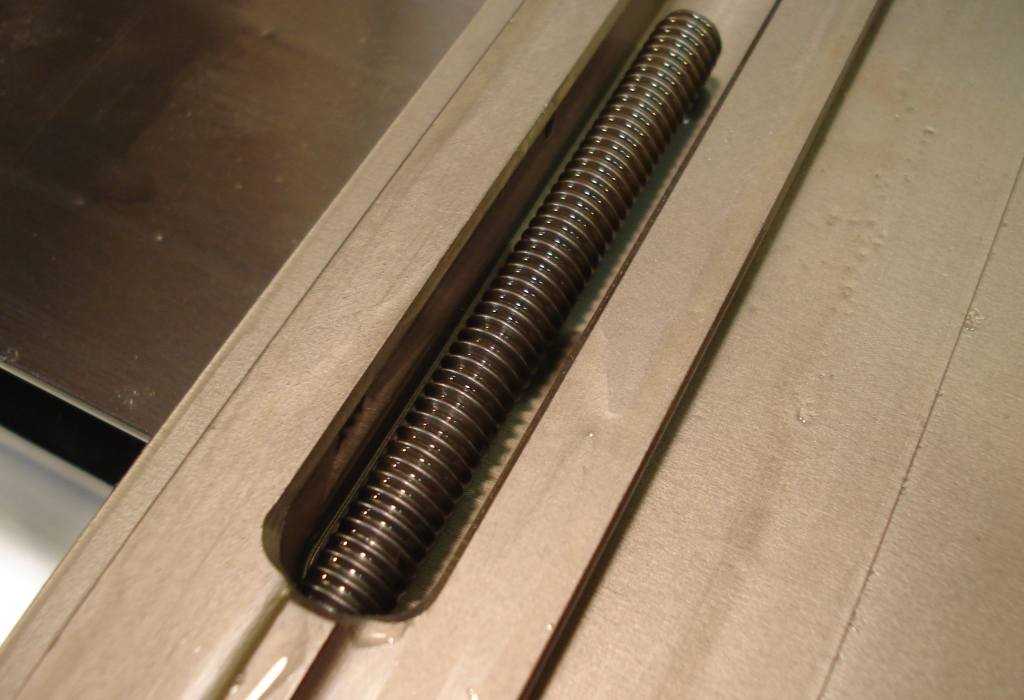

| Leadscrew end. The flat is for the dial setscrew to bear against. |